Zhengrun Rb380high Speed Rigid Box Premuinm Box Gift Box Shoe Box Sweet Box Machine with YAMAHA Robot

Basic Info

| Model NO. | RB380 |

| Warranty | 1 Year |

| Certification | ISO9001, TUV, GMP, ISO, CE |

| Application | Commodity, Machinery & Hardware, Textile, Alcohol, Toy, Chemical, Apparel, Gifts & Arts, Dining, Medical, Food |

| Driven Type | Electric |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Type | Paper Packaging Equipment |

| Automatic Grade | Automatic |

| Power | 20kw |

| Shipping Method | Sea/Train/Air |

| After Sales Service | on Site Installation and Online Service 7*24 Hours |

| Trade Mark | Zhengrun |

| Labor Required | 1 Worker |

| Payment Term | Tt/LC D/P |

| Transport Package | Wooden Case |

| Specification | 7000*1600*1250MM |

| Trademark | Zhengrun |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 888888 |

Product Description

Product Description

Sample

Product Features

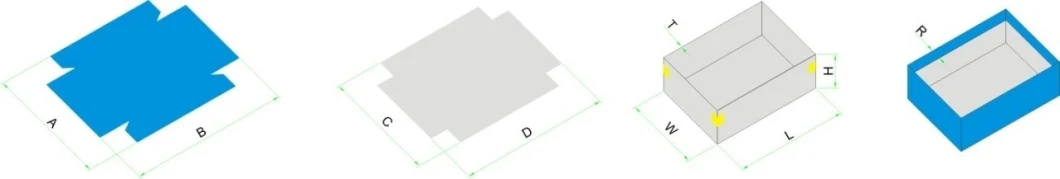

W+2H-4T≤C(Max) L+2H-4T≤D(Max)A(Min)≤W+2H+2T+2R≤A(Max) B(Min)≤L+2H+2T+2R≤B(Max)

| RB380 Automatic Rigid Box Maker | |||

| 1 | Box size(A×B) | A(min) | 70mm |

| A(max) | 480mm | ||

| B(min) | 120mm | ||

| B(max) | 630mm | ||

| 2 | Paper thickness | 100-300g/m2 | |

| 3 | Cardboard thickness | 0.8~3mm | |

| 4 | Finished product (carton) size (W×L×H) | W(min) | 50mm |

| W(max) | 260mm | ||

| L(min) | 60mm | ||

| L(max) | 380mm | ||

| H(min) | 12mm | ||

| H(max) | 120mm | ||

| 5 | Folded edge size(R) | R(min) | 10mm |

| R(max) | 100mm | ||

| 6 | precision | ±0.10mm | |

| 7 | speed | <=50pcs/min | |

| 8 | Motor power | 28kw/380v 3phase | |

| 9 | Electric heating power | 6kw | |

| 10 | Machine weight | 5500kg | |

| 11 | Machine dimension(L×W×H) | L6300×W6000×H 3300mm | |

Detailed Photos

Company Profile

Zhejiang zhengrun Machinery Co., ltd

Zhejiang zhengrun Machinery Co., ltd.,established in 1997, is the first domestic brand to start the business of the business of packaging equipment production. The Company is mainly engaged in the R&D, design, production and sales of the rigid box machinery and case maker machine. It's rated as a National High-Tech Enterprise, National Intellectual Property Advantage Enterprise, Provincial enterprise R&D center, Wenzhou Civilized Unit, Pingyang County New Age Civilization Practice Enterprise Culture Demonstration Base.

The company has the modern standard factory buildings covering 66,000 square meters,as well as a highly professional R&D and production team and the world's leading super-large production and processing center. Zhengrun's packaging equipment can be applied to the gift box packaging of many brands in multiple fields, such as fields of electronics, cosmetics, jewelry, wine, clothing and shoes, food and drink (like moon cakes and tea), desk calendars, and notebooks. The company has the right to import and export,and has gained the certification of ISO9001 quality management system with all products gained the European CE product certification. The products and services now cover more than 80 countries and regions .Since its inception, the company always adheres to the business development concept of considering that "quality Builds Zhengrun Brand". the company passes on the artisan spirit, pursues higher quality and aims to establish a stronger brand , so as to become the world's representative "Made in China" brand in printing and packaging industry!-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------1.Our own Machining center>>>>>>>>>>>>>>>>>>>>>

Mazak uses its own advanced production equipment, including 5-axis turn-milling complex processing unit, gantry 5-axis processing machine, mixed-line FMS composed of turn-milling complex machining center and horizontal machining center, etc. In the constant temperature and humidity precision machining room, precision parts through ultra-precision equipment production, with a high degree of flexibility,) processing precision of high precision CNC machine tools individual processing precision up to 0.05-0.1mm, processing quality stable, reliable processing of the same batch of parts, in the same machine tool, under the same processing conditions, using the same tool and processing order, The tool path is complete and identical, the consistency of the parts is good, and the quality is stable. So that the final machine will have better performance.

-----------------------------------------------------------------2.Spare Parts Warehourse>>>>>>>>>>>>>>>>

Advanced 7S management ensures the company's elegant production and office environment,but also to improve work efficiency ,production of high quality ,reduce waste ,save material costs and time cost.

_

_____________________________________________________________________________________________________________________

3.Packing and Shipping>>>>>>>>>>>>>

______________________________________________________________________________________________________________________

4.Patent>>>>>>>>>>>>>>>>>>>>>>>>>>

______________________________________________________________________________________________________________________

5.Exhibition>>>>>>>>>>>>>>>>>>>>>>

FAQ

1.How long will it will take your engineer be there ?Generally speaking:Within one week after you receive the machine.2. How many days required for machine installation?Depend on machine type and proficiency of your operator,normally it will take 15-20 days 3. What i need to pay for installation?Engineer's visa , air tickets, hotel, food ,and also their salary 150USD one day per person is covered by customer4. How long warranty period?One year5.How to select the machine?If you don't have any experiences for this business,no problemJust let us know your budget and the product you want to make,we will tailor-made the solution accordingly6.How could get after-sale service?We have service team work 7*24 hours,if any questions during use,we can have a video conference to guiding you how to solve problem7. Does your engineer understand English?Our engineer understand a little English. All our engineer have more than five years machine installation experience. In addition, the sales will work together with our engineer to serve our customer8.Is customization available? Yes, Our R&D team can design the machine according to your needs 9. How do we solve the machine problem after your engineer leaving?Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our sales at any time. Our engineer will take a solution video according your description.10. How many worker do we need running those machines?Depend on the machine type,if fully automatic machine ,you just need one or two operator for each machine.11.What about the security of my payment?We have alibaba account,if you are worried about it,you can pay through alibaba, alibaba provide assurance service,we can only receive money after shipment.